- Share

- Share on Facebook

- Share on X

- Share on LinkedIn

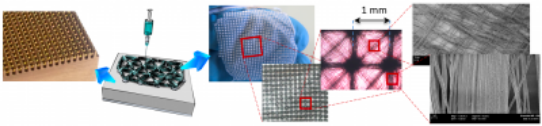

Under the action of the intense electric field (involving voltages that can reach several tens of kV), a jet of polymer solution is emitted from the tip of the hanging droplet (Fig. 1 a). Charged on the surface, this jet is accelerated and stretched (Fig. 2 b). The solvent evaporates in the first few centimeters of the jet's propagation in the air, resulting in a nanofiber of polymer collected on a substrate (Fig. 1 c). This process enables the production of membranes composed of fibers with diameters ranging from nano to micrometric.

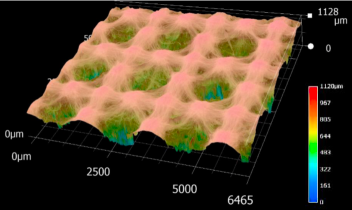

The fabrication of nanofibrous materials has applications in numerous industrial sectors such as filtration, technical textiles, catalysis, energy (membranes for fuel cells), and detection (sensors). A major challenge for these applications is to develop lightweight yet mechanically strong structures. We are working on structuring nanofibrous membranes to impart specific mechanical properties (Fig. 2).

Tissue engineering is the application we promote through the ANR BioScaff project. The goal is to develop new implants for soft tissue reconstruction, combining properties of biocompatibility, biodegradability, and hyperelastic behavior similar to that of host tissues. This project specifically aims to establish a set of complementary experimental, theoretical, and numerical studies, ultimately allowing for the optimization of the mechanical behavior of bioreabsorbable scaffolds specific to soft tissues.

References :

[1] Garcia Garcia C. E., Soltero A., Bossard F. and Rinaudo M., « Biomaterials based on electrospun chitosan/PEO blends. Relation between processing conditions and mechanical properties » Polymers, Special Issue « Advances in Chitin/ Chitosan Characterization and Applications » 2018.

[2] Mengistu Lemma S, Bossard F and Rinaudo M., « Preparation of Pure and Stable Chitosan Nanofibers by Electrospinning in the Presence of Poly(ethylene oxide) » Int J Mol Sci. 26 ;17(11), 1790, 2016.

[3] Bourourou M., Holzinger M., Elouarzaki K., Le Goff A., Bossard F., Rossignol C., Djurado E., Curtil D., Chaussy, D., Maaref A., Cosnier S., « Laccase wiring on free-standing electrospun carbon nanofibres using a mediator plug » ChemComm, 51, 14574-14577, 2015.

[4] Bourourou M., Holzinger M., Bossard F., Hugenell F. Maaref A., Cosnier S., « Chemically reduced electrospun polyacrilonitrile–carbon nanotube nanofibers hydrogels as electrode material for bioelectrochemical applications », Carbon, 87, 233-238, 2015

Personnel Involved

- Share

- Share on Facebook

- Share on X

- Share on LinkedIn